Home> Company News> Experimental study on microwave drying of Pu erh tea

- AddressAddress: No. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Worktime9:00-18:00

- Phone(Working Time)Tel:+86 0531 85064681

- FaxFax:+ 86 0531 85064682

Experimental study on microwave drying of Pu erh tea

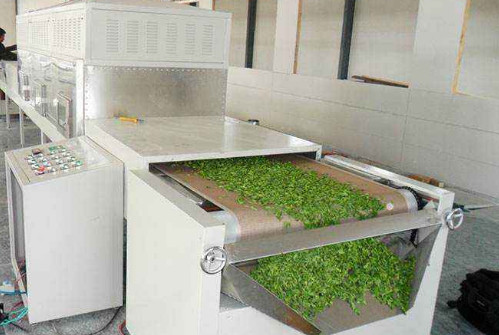

2018-11-02 10:27:41Tea microwave dryer disinfector is a new and efficient drying equipment, using microwave oven equipment to dry rose buds, can be dual-purpose, can kill, can also be dried!

Microwave drying is different from conventional drying method. When conventional drying, the temperature of materials increases from outside to inside, and the water loss rate decreases gradually from outside to inside. The shortcomings of this drying method are that the water content in inner layer is much larger than that in outer layer, and it is easy to form a drying shell in outer layer, which affects the drying speed and quality. For Pu'er cake tea, the water loss in outer layer is too much. In microwave drying, the material is heated layer by layer from inside to outside, and water loss is also from inside to outside, so it is not easy to form a drying shell, and water loss is fast and uniform. Microwave drying materials, water loss rate is affected by heating time and power.

The curves of drying temperature and water loss rate of mechanical cake tea heated by microwave were obtained through the single drying test of microwave. The curves are shown in Fig. 2 and Fig. 3 respectively. It can be seen from the figure that the temperature is proportional to the time in microwave drying. With the prolongation of heating time, the temperature also rises.

The water loss rate decreases gradually, then increases, and then decreases gradually. The reason for the final decrease may be that the water content of cake tea itself is very low, and the water is not easy to lose.

The optimum technology of microwave drying Pu'er tea is that each cake is heated for 320 seconds and kept warm for 320 seconds. In order not to affect the quality of Pu'er tea, this technology is based on controlling the temperature and water loss rate. The drying efficiency and power consumption are further determined. The results show that it will not affect the quality of Pu'er tea, on the contrary, it will not affect the quality of Pu'er tea. Compared with the traditional drying method, the drying efficiency has been greatly improved, while the processing cost has been reduced. More importantly, microwave drying will not pollute the environment and contribute to environmental protection. Based on the above advantages, it can be seen that microwave drying of Pu'er tea is completely feasible, and it can speed up the development of Pu'er tea industry. The exhibition is of great significance.

Animal Aquarium Pet Dog Cat Monkey Fox Bird Tilapia Floating Fish Feed Pellet Production Machine Snack Food Mill Processing Making Extrusion Line for Sale

Animal Aquarium Pet Dog Cat Monkey Fox Bird Tilapia Floating Fish Feed Pellet Production Machine Snack Food Mill Processing Making Extrusion Line for Sale Animal Aquarium Pet Dog Cat Monkey Fox Bird Tilapia Floating Fish Feed Pellet Production Machine Snack Food Mill Processing Making Extrusion Line for Sale

Animal Aquarium Pet Dog Cat Monkey Fox Bird Tilapia Floating Fish Feed Pellet Production Machine Snack Food Mill Processing Making Extrusion Line for Sale Various Shapes Fish Food Processing Line /Pet Food Production Line

Various Shapes Fish Food Processing Line /Pet Food Production Line China Manufacturer Pet Food Fish Feed Processing Line

China Manufacturer Pet Food Fish Feed Processing Line Animal Aquarium Pet Dog Cat Bird Tilapia Floating Fish Feed Pellet Production Machine Snack Food Mill Processing Making Extrusion Line Price

Animal Aquarium Pet Dog Cat Bird Tilapia Floating Fish Feed Pellet Production Machine Snack Food Mill Processing Making Extrusion Line Price

Oil Mill Machinery China Manufacturer cold press oil machine soy protein production line Auxiliary Machine For Oil Press Continous Single Layer Mesh Belt Dryer Conveyor Dryer Hot air drying oven Fruit and vegetable drying machine Micro Wave Oven fastfood microwave fast heating equipment Multi-layer Oven Bread Crouton chips line Sweet potato starch machine twin screw extruder Stretch Film Machine Rolls Starch modified machine floating fish feed extruder machine Artificial rice extrusion line Frying Instant Noodles machine Japanese Peanut Equipment starch machine Nutritional Powder extrusion line Microwave drying machine TOFU PRODUCTION LINE Single screw extruder Pop cereals grains machine snack pellet production line Potato chips production line Chocolate Bar Machine 123